Job Description

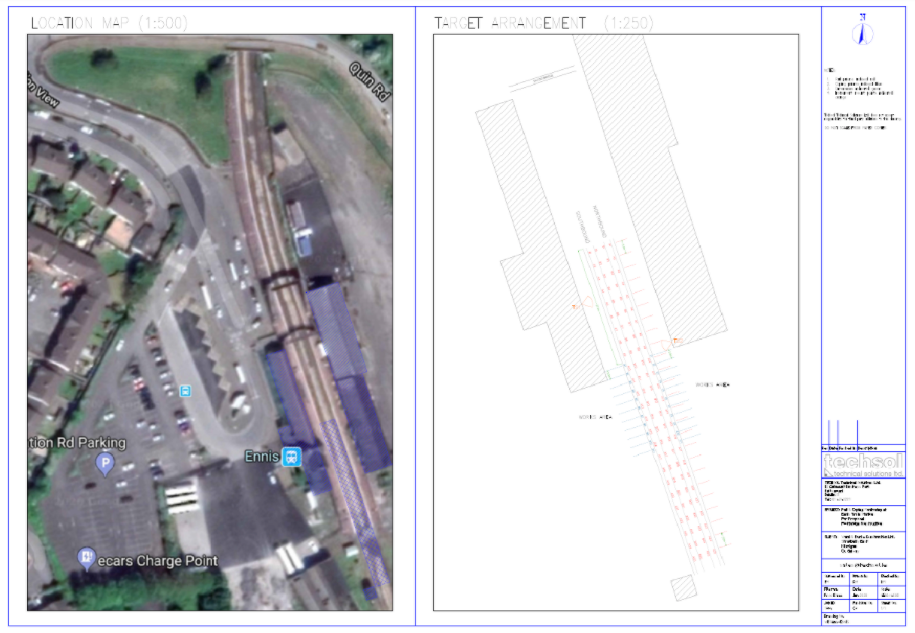

4 No. 77m lengths of rail (2 rail roads) at Ennis Train Station were to be monitored during works associated with the construction of a new footbridge linking the southern ends of the 2 platforms.

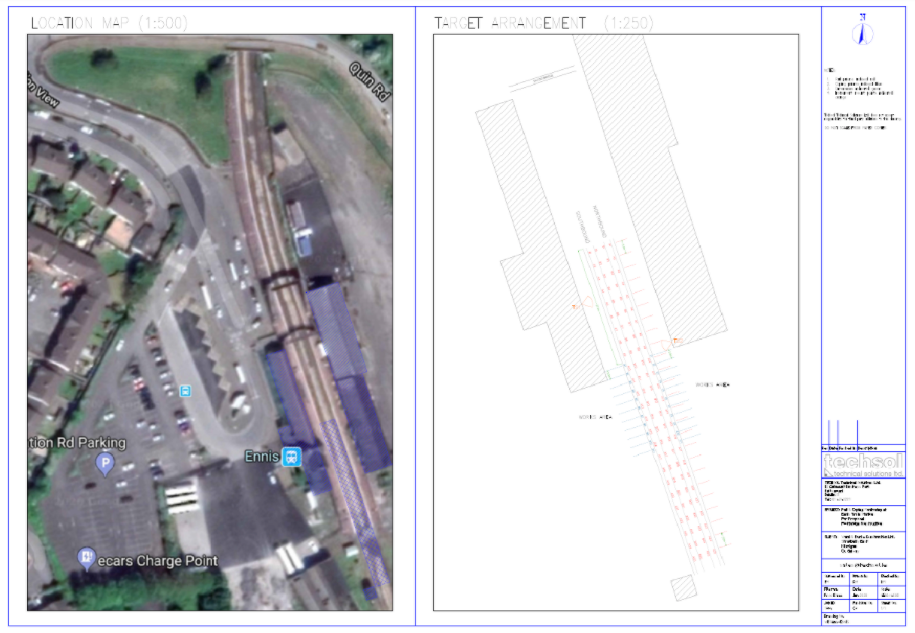

Monitoring prisms were installed at 3-metre intervals as per Irish Rail document ‘CCE-TRK-SPN-010 Specification for Movement Monitoring of Railway Track and Digital Safety File Requirements’. Coping stones were also to be monitored at 2m centres over a length of 23m on each side.

The general arrangement of prisms was as per the layout in drawing WB7864-ENNIS.

The prisms were installed at the required locations using a water-resistant bonding compound.

Equipment

- Trimble R12 to establish ITM referenced control on site

- Trimble SX10 to carry out the top-of-rail survey (for calculation of vertical offsets)

- Trimble S9 Robotic Total Stations with Finelock technology for regular monitoring observations

- Trimble set-top boxes to relay observation data via a 4G connection to a remote computer running Trimble 4D Control monitoring software

Survey Control

A number of prisms were installed remote from the works area, and out of reach of the general public, to be used as control points. The instruments referenced these prisms to orientate themselves before each observations pass.

Baseline Observations

In advance of regular monitoring commencing, a set of baseline observations were required to assess the track geometry, and also to provide a baseline to which subsequent sets of observations could be compared.

Daily Monitoring

Driven by Trimble T4D, the instruments would orientate themselves by observing the control prisms prior to collecting each set of observations. It was intended that by running some code at the back end the target observations would automatically populate the Irish Rail monitoring spreadsheet calculating vertical movement, cant, short twist and long twist.

This would then be reviewed by the monitoring manager for spurious readings before being transmitted via email to the Employer’s representative and the other nominated recipients. An automated text alert would issue should any cells turn amber or red.

We expected that approximately 60 sets of observations would be collected automatically per 24hr period. The daily sheet would contain an average of all observations for that period.

Difficulties Encountered and Resolved

- It was initially proposed that a single instrument be installed in a protective cage and mounted on the closed footbridge approximately 40m north of the monitoring area as indicated on drawing WB7864-ENNIS. This is outside of the zone of influence. Unfortunately, when we tested this location, we found that there were difficulties reading several of the prisms due to multiple prisms in the field of view competing to lock the instrument.

- Following further testing, it was decided to install an instrument on each platform, much closer to the zone of influence. This gave us a robust monitoring solution that ensured that there would be no unnecessary interruption to the works.

- About 3 days into the pre-construction monitoring stage we stopped receiving data from one of the instruments.

- Following some investigation, we discovered that one of the set-top boxes had malfunctioned and we replaced it immediately with a time-tested unit, so there was no impact on the delivery of reports or the commencement of works in the zone of influence.